The premade pouch packaging machine has advantages in many aspects (if you don’t know it, you can read our Premade Pouch Packing Machine VS Form Fill Seal Machine). There are have two types of premade pouch packaging machines on the market——rotary packaging machine and horizontal packaging machine. We briefly introduce the similarities and differences between the two types of machines, hoping to help people who do not know which one to choose.

Rotary Packaging Machine

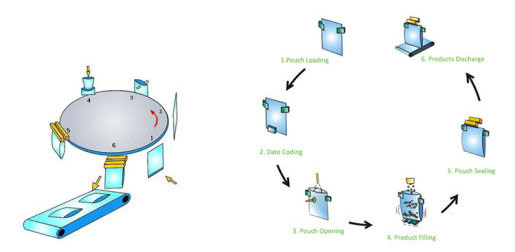

As the name suggests, the Rotary Packaging Machine is to feed the premade pouch into a rotating turntable. The pouch rotates to different workstations with the turntable, and a series of packaging operations are usual.

The mainstream models have about 6-12 workstations. The more workstations, the more flexible and the more functions that can be implemented. It runs like the following picture:

Horizontal Packaging Machine

The Horizontal Packaging Machine adopts a horizontal direction. The overall workflow is similar to that of the Rotary Packaging Machine, and it is also divided into many stations. It runs like the following picture:

Speed

In many cases, the packaging speed of the machine depends on the filling speed, so there is no difference in the speed of the two for those products with a slower filling speed. Some products have a faster filling speed. At this time, the packaging machine becomes a bottleneck. In general, the speed of the two is similar. However, if the Horizontal type adopts the double bagging method, its speed can be slightly higher than that of the Rotary type, reaching about 100 bags. And Rotary type with the double bag can reach 125BPM. However, the price of the double-bagging machine is higher, and the filling volume is lower. At the same time, you need to purchase two sets of filling equipment. If your workshop has enough space, it is better to buy two sets of packaging equipment.

Another factor that affects the speed is the weight of the products. Because of the centrifugal force generated when Rotary type rotates, it needs to be slowed down to maintain smooth operation when packing heavier products. Simply put, at the same speed, Horizontal type tends to be more stable than Rotary type.

Filling Volume

Horizontal type is at a disadvantage in filling volume because its horizontal width limit makes Horizontal type’s filling volume much smaller than Rotary type.

In terms of accuracy, the two are the same, because the filling machine actually determines the accuracy, and both can have enough filling time.

Pouch Type

There is not much difference between the two types of pouch. Both Rotary type and Horizontal type can be perfectly adapted to the most prefabricated pouch. In terms of pouch width, Rotary type has an advantage. As mentioned before, the horizontal type’s pouch width is narrower.

Price

If other factors are the same, the prices of the two are similar. However, Rotary type can often have a large filling volume and a larger bandwidth, so in fact, the Rotary type cost performance will be higher.

Repair & Maintenance

Because the Horizontal type control system and the turntable are located behind the fuselage and the Rotary type is located below, the Horizontal type is easier to maintain. Horizontal type can open the maintenance door more conveniently and troubleshoot errors. When repairing the Rotary type, the debugger needs to squat or lie down to see the internal system underneath.

Another difference between Rotary type and Horizontal type is the bag width adjustment. Rotary can easily change the width of the bag. You only need to modify the settings on the control panel or rotate the pitch adjustment knob, and the machine will automatically change the distance between all grippers to adapt to the width of the bag. The horizontal type adjustment of the bandwidth is inconvenient. The debugger must replace some parts to achieve the purpose of adjusting the bag width, which takes a long time and requires additional costs.

TL;DR

On the whole, Rotary type is better than Horizontal type. Most customers also choose Rotary type. Rotary packaging machine has more than 95% market share. However, in some cases, you can also choose Horizontal type. For example, if you need a small dose, high precision, and high speed, the price of Horizontal will be cheaper.

The above content was updated in 2021.5.6 because the packaging industry has been developing, so some content may be out of date, and we will come back to update them from time to time.