Automatic Gravity Filling Machine & Liquid Bottling line

| Capacity | 80 BPM |

| Nozzles | 8 – 16 |

| Filling Range | 100 – 5000ml |

| Accuracy | ±1% ~ 2% |

Automatic gravity liquid filling machine is using the principle of time flow design, is suitable for filling liquid material or high foam and low-viscosity liquid(If you want to fill high-viscosity liquids, you can choose our Piston Liquid Filling Machine). It is a nice choice for filling low viscosity products in daily chemical, washing, medicine and food. The machine has 3 filling models: straight through, drip-proof and lifting, and it can be configured with 8, 10, 12 and other different quantities of filling head, users can choose the type of machine they want according to actual needs.

Features

Parameter

| RJ-AGF8 | RJ-AGF10 | RJ-AGF12 | RJ-AGF16 | |

|---|---|---|---|---|

| Nozzle Number | 8 | 10 | 12 | 16 |

| Filling Volume | 100 – 5000ml | |||

| Production Capacity | 1000 – 5000Bottle/Hour (Depends on filling volume) | |||

| Quantitative Error | 100 – 1000ml: ≤ ±2%, 1000 – 5000ml: ≤ ±1% | |||

| Voltage | AC220V 380V ±10% | |||

| Consumed Power | 1.5kw | |||

| Air Pressure | 0.6 – 0.8mpa | |||

| Air Consumption | 0.8m³/min | 1m³/min | 1.2m³/min | 1.2m³/min |

Bottle Style

Industries & Solution

Detergent, Washing Fluid, Soy sauce, Rice vinegar, Juice, Tomato paste, Peanut paste, Fruit paste, Chili sauce, Bean sauce, etc.

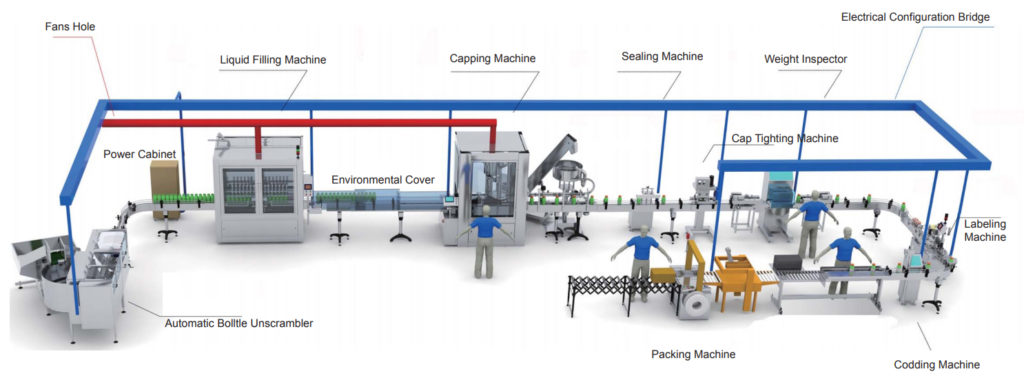

Bottling Line

By combining Linear Capping Machine and Bottle Labeling Machine, a highly automated Bottle Line can be formed.

Learn More

Learn more about liquid packaging machine —— What is liquid packaging machine