When your machine travels through a long journey and finally comes to you, you must be full of joy. This is the beginning of a new production experience, It’s better to have someone in your company know the main points of mechanical maintenance. Machines are different from humans, and they cannot provide timely feedback on their own conditions, and require continuous inspection and participation by users to extend the service life of machines to the longest.

Every customer who purchases machinery, in order to minimize damage to the equipment you purchase, and to bring you the most comfortable user experience, the operators you equip the machinery with should understand the repair and maintenance of the equipment, according to their maintenance, repair capabilities and the familiarity with the equipment, we can divide it into junior technicians and intermediate technicians.

Junior Technician

Junior technicians are mainly responsible for the daily maintenance and simple repair of equipment.

Equipment Maintenance

After the equipment is unpacked, before the first use, and during the daily use of the machine, junior technicians need to inspect the machine. The main inspection components are the whole machine clamp, bag feeder, vacuum chamber, filling system, and trays, etc. Junior technicians need to ensure that these parts are free from foreign matter, noise, loosening, and other unusual phenomena before use, at the same time, check that the protective cover is intact and that the safety device is sensitive and effective. This is the prerequisite for the stable and smooth operation of the machine, and it is also a very important procedure to ensure the safety of personnel when the machine is used.

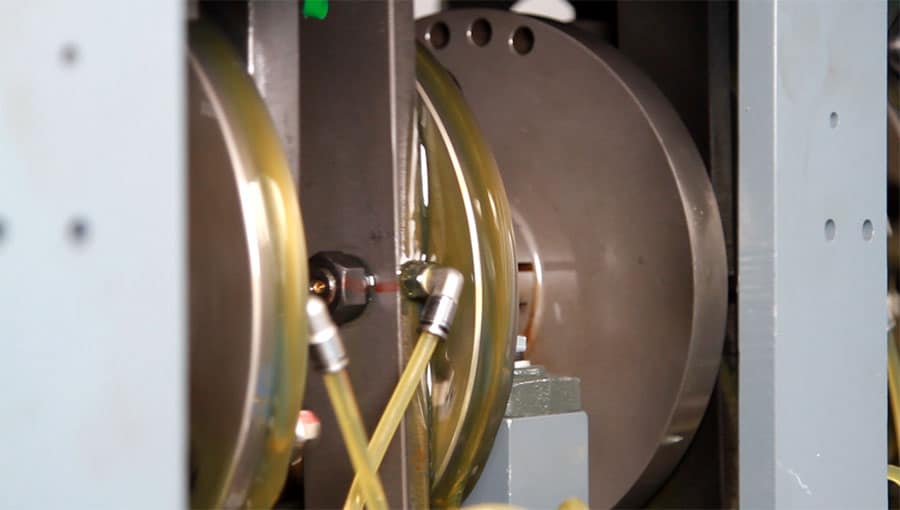

Vacuum turntable and bag feeding turntable are two main parts of packaging machinery, which directly affect the final packaging effect. Therefore, these two parts should be subjected to daily maintenance work such as inspection of movable bushings and Joint bearing, lubrication, and tightening of screws. In addition, the gears and guide rails of the vacuum turntable should also be taken care of and regularly lubricated. If there is a problem with these two parts, the effect of the packaging will inevitably be affected, and it will further affect the income, which we do not want to see.

In addition, junior technicians also need to check the oil level of the pneumatic triplet and the blockage of the filter. Also, check each compressed air pipe to ensure that there is no air leakage, that the cooling water pipe does not leak water and the pressure is normal, and that the water level of the cooling water tank is normal and there is no leakage.

A huge machine is composed of many small parts. Even a small screw plays a decisive role in the normality of the machine. Loose screws are the easiest to solve but also the most common problem. Usually, we need to pay special attention to the condition of the screws to ensure there are no mistakes at the critical moment of mechanical operation.

The above are the daily inspection items that junior technicians need to do before using the machine for the first time and before using the machine daily.

Simple Maintenance

In addition to daily inspections, junior technicians also need to perform simple maintenance on the equipment according to the inspection, such as timely replacement of suction cups, heat sealing sheets, and silicone strips, etc. And adjustment of the tightness of the conveyor belt. The vacuum chamber is very important for the tightness of the vacuum product. If the sealing strip is damaged or aging will affect the normal operation of the machine, the vacuum packaging effect will also be problematic.

The mechanical equipment needs to adjust the various parameters of the mechanical operation through the size of the packaging bag in time, this also requires the participation of junior technicians. According to the requirements of the product packaging bags, adjust the machine clamping, bag feeding, turntable speed, filling speed and capacity and heat sealing, etc.

According to the responsibilities of junior technicians, it is also necessary to check the safety measures and performance of the protective cover of the equipment, and install the missing external screws of the equipment. Junior technicians need to adjust and modify various parameters according to product requirements.

Intermediate Technician

In addition to the equipment maintenance and repair duties, corresponding to the junior technicians, the intermediate technicians also need to be responsible for the annual or quarterly maintenance of the equipment, and they also need to be responsible for some more complex repairs.

Equipment Maintenance

Regarding the equipment maintenance of intermediate technicians, it is mainly about two aspects. One is the first-level maintenance during each vacation; the second is the second-level maintenance once a year.

First-Level Maintenance

Throughout the year, the equipment is always used day after day, so the rare three to five days vacation is an important time for major maintenance of the equipment, just like people under long-term stress need vacations to relax and adjust the state. Maintenance of the machine during the holidays is very important and must be done.

During the holidays, the main things that intermediate technicians do are:

- It is necessary to check the oil level of the main drive motor and reducer. If it is insufficient, replenish it in time.

- Check the main transmission bearing and cam of the machine body, adjust the screws in time, and tighten them. At the same time, add oil to lubricate the parts.

- Check and replenish the oil level of the vacuum pump, check and tighten the vacuum pipe joints.

- Check and adjust the sealing performance of the air distributor, if there is a problem, add vacuum silicone grease in time.

- Check the various parts of the equipment, such as trays, machine clamps, vacuum chamber, conveyors, chillers, etc.

The above inspections and adjustments are all in order to allow the machine to operate normally in the next working cycle and reduce the occurrence of faults and problems. For some models, we are also equipped with automatic maintenance functions, such as automatic lubrication system

Second-Level Maintenance

Second-Level maintenance is recommended at least once a year. The main content of the Second-Level maintenance is to replace the oil of the main engine, reducer, and tray. Replace the vacuum pump oil and the filter includes air filter element and exhaust filter element.

Equipment Repair

In addition to First-Level Maintenance and Second-Level Maintenance, intermediate technicians also need to repair the equipment. The main contents are:

- Deal with and replace the air leakage of the air distributor and vacuum exhaust pipe.

- Adjust and repair the material box, filling system, and air cylinder.

- When the failure of the heat-sealed parts is not caused by the failure of electrical and mechanical parts, intermediate technicians need to troubleshoot and deal with problems such as insufficient air suction and poor sealing of the heat-sealing.

- Replace the damaged cooling water pipe joints, air joints, and air pipes.

- Handle simple the machine running, emitting, dripping, and leaking faults. When high temperature and high pressure are involved, professional maintenance personnel are required to participate.

Other

Besides, some special climate also require special maintenance, for which we wrote —— Guidelines for safe winterize of packaging machines. In addition to correct operation, the normal use of equipment also requires attention to daily maintenance. This is the best way to save costs.

This guide applies to our premade pouch packaging machines and automatic vacuum packaging machines.