Light, the most common substance, is hard to capture, but it affects our daily lives all the time.

People have used light as a resource for a long time. The use of light plays an irreplaceable role in the development of human society.

Origin and History

People’s research on polarized light began in 1669. Danish scientist Rasmus Bartholin discovered that birefringence occurs when light passes through the Iceland spar, that is, two beams of light are refracted. Of these two lights, one follows the known optical theory at that time, while the other is an “unusual light” outside the scope of people’s theoretical knowledge. Rasmus Bartholin was unable to explain this phenomenon with the known optical theory at the time. Therefore, since then, people’s theoretical research on light has taken on a new direction.

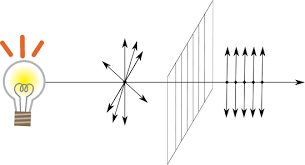

The concept of “polarization” originated from the “father of polarization”: Étienne-Louis Malus. His painstaking research, deduced from the experimental results known Malus’s law: I = I (Ο) cos²θ. (where “I” is the initial intensity and ”θ” is the angle between the light’s initial polarization direction and the axis of the polarizer). This research result is of great significance for future optical research.

Since then, a steady stream of people have joined the research team of optical principles, and the theory of optics has been constantly developing and improving.

Application and Development

In the current social development, the principle of light polarization is widely used in various occasions. Polarization theory of light is used in geology, seismology, chemistry, astronomy, and other fields.

In the food packaging industry, polarized light is also quietly playing a role.

The heat-sealing of the package is a process in which the plastic packaging material used for packaging is appropriately melted by increasing the temperature, and then a certain pressure is applied to re-bond the plastic packaging material.

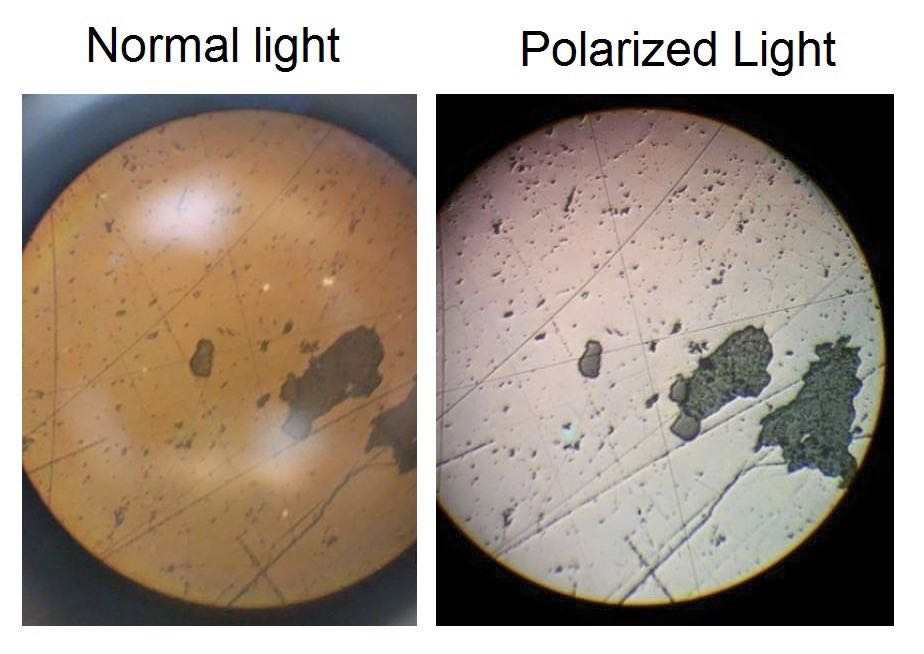

During the heat-sealing process, as the temperature rises, the original polymer chains are broken and the hydrogen bonds change, which causes the material to pile up even more tightly. For some plastic films, the birefringence principle of polarized light can be used to enhance the observation of thermal seal conditions. The reason for this operation is to judge the heat seal of the plastic film by comparing the difference in the transmittance of visible light through the plastic film.

After the temperature rises, under the action of pressure, a series of changes of the sealing material are the prerequisites for determining the change of visible light transmittance. According to the light transmittance, the crystallinity of the seal can be further inferred, and the uniformity of crystallization in the seal area can also be checked.

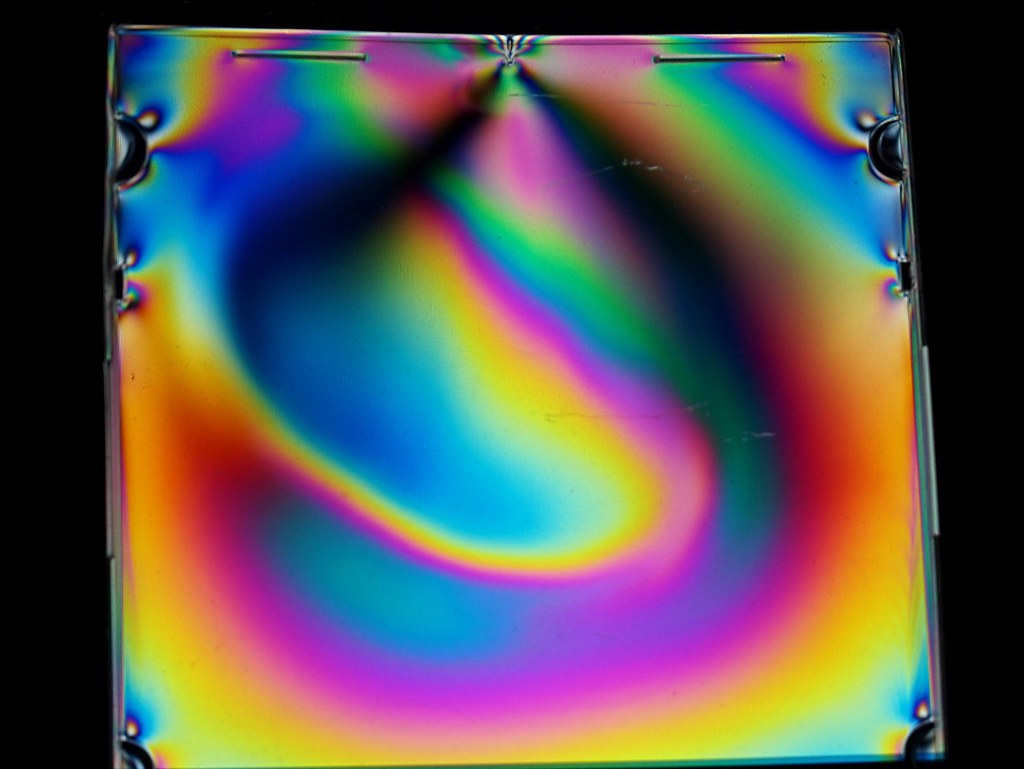

From the common understanding, the uniform crystallization, that is, good sealing effect. Under the irradiation of visible light, the overall sealing area will show a similar color tone. When the crystallization is not uniform, that is, the sealing effect is not good, the different sealing effect will show a different color of light.

The color of the light will be different because of the difference in sealing material and thickness. However, in the same sealed packaging, people can according to the light through the plastic film sealing presented by the different colors, to judge whether there is uneven heat-sealing crystallization on the packaging sealing.

In industrial applications, the use of polarized light can quickly help people identify defects in the heat seal. But the process has rarely been used in practice. There are many reasons for this, among which cost and efficiency are the two biggest factors. In the operation process of the packaging machinery used today, after the heat-sealing seal is recognized by polarized light, heat-sealing packages with poor sealing performance cannot be effectively selected and reheat sealed. Secondly, people’s requirements for heat-sealing have not reached a very strict evaluation standard, and a small part of the defects left in the heat-sealing will not have a great impact on the packaging and the materials in it. Under the dual pressure of cost and efficiency, the detection of heat seal is gradually reduced in practical use.

There are many ways to check the heat seal, and the use of polarized light is only one of them.

Refer:

https://en.wikipedia.org/wiki/Heat_sealer

https://en.wikipedia.org/wiki/Polarization_(waves)

https://en.wikipedia.org/wiki/Birefringence

https://www.ni.com/en-us/innovations/white-papers/06/inspecting-transparent-materials-for-material-defects.html

https://www.fda.gov/food/laboratory-methods-food/bam-chapter-22c-examination-flexible-and-semirigid-food-containers-integrity